Design and manufacture of the ball mandrel of the pipe bending mould

Source:Liye Machinery(LYM) Co.,Ltd Release time:2021-10-08 13:14:55 Visit:2723

Design and manufacture of the ball mandrel of the pipe bending mould

This article is about the design and production of the ball mandrel for pipe bending die. Since many customers and friends asked me about this,so I spent a little time to sort out. In fact, these have national standards.

1. First determine the type of mandrel (probably summarized several):

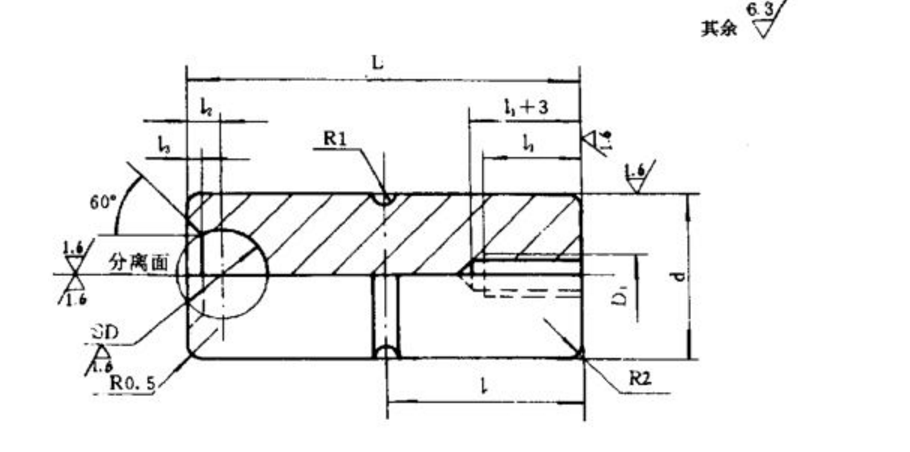

A. Straight head mandrel(for thick-walled metal pipe)

B. Curved mandrel( for thick-walled tubes with small radius)

C. Standard universal mandrel( for standard pipe wall thickness and bending radius )

D. Ultra-thin mandrel for bending thin-walled tubes with small radius

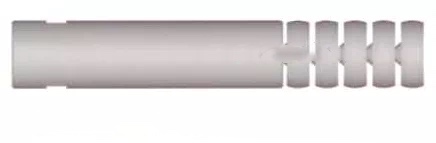

2. When selecting the type of mandrel, the number of balls and the wiper die, the following formula can be used:

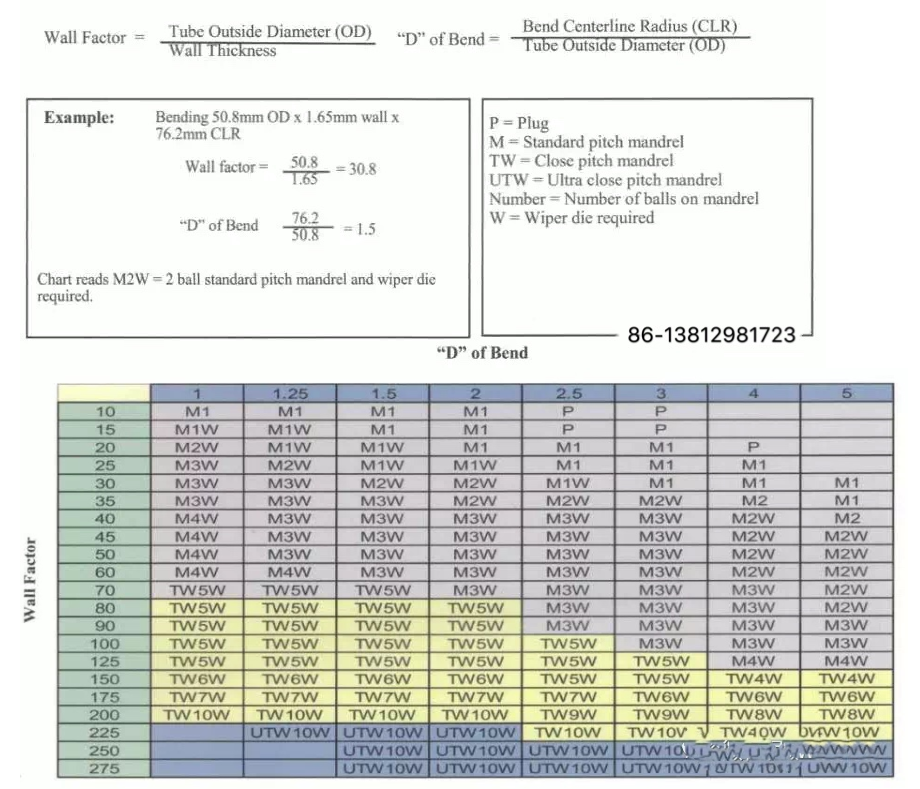

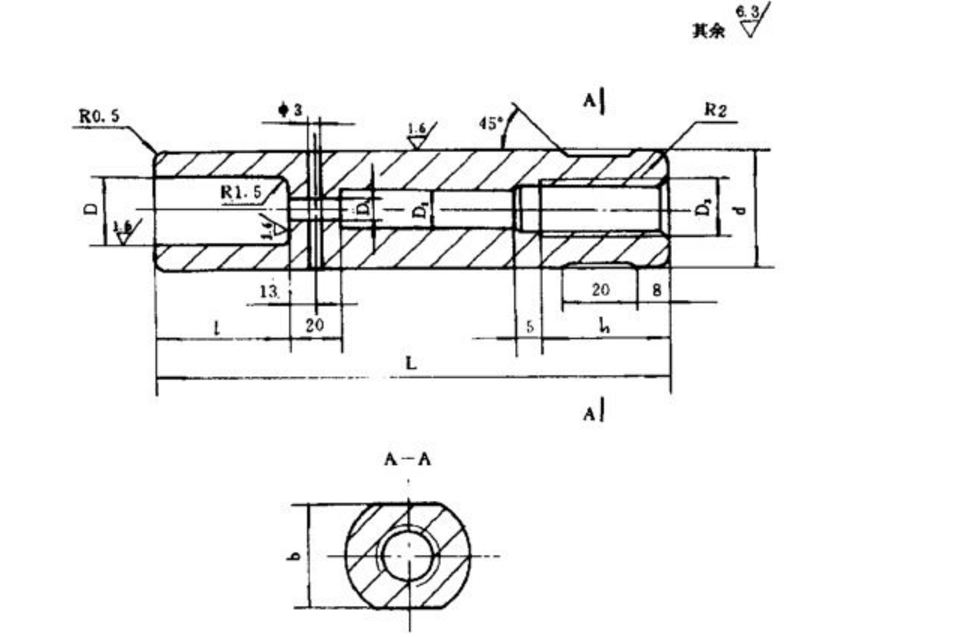

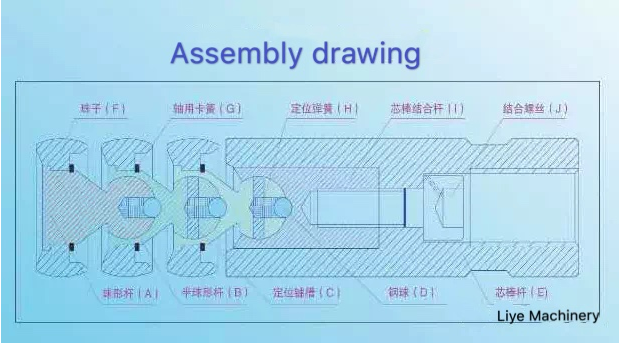

3. Introduce the structure of standard universal mandrel

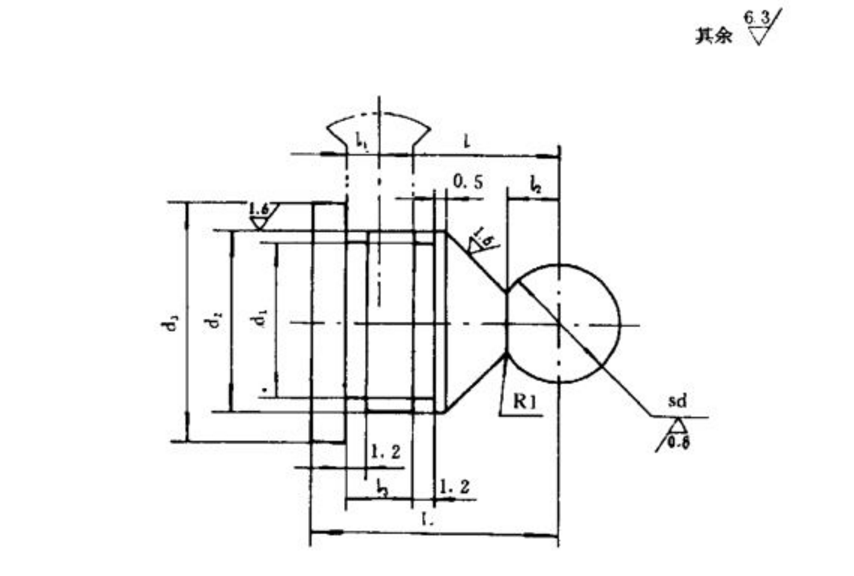

Ball mandrel head

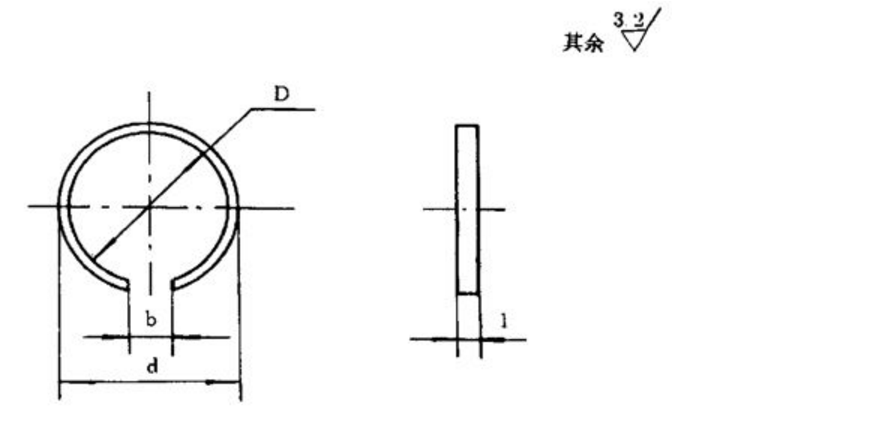

Retaining ring

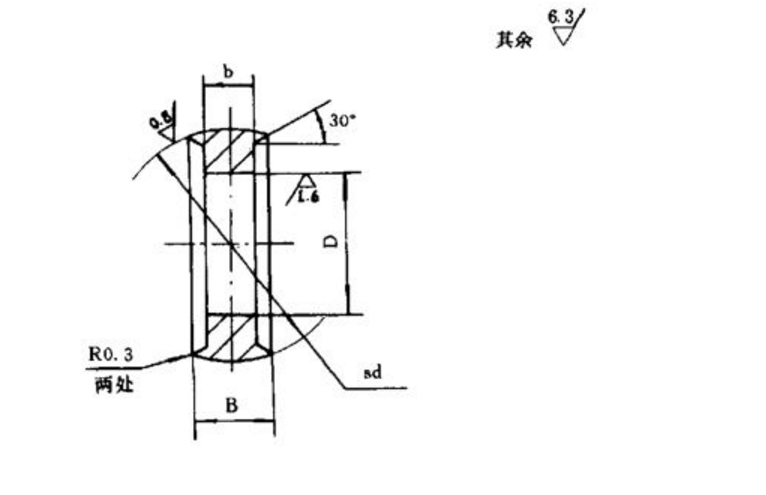

Ball head

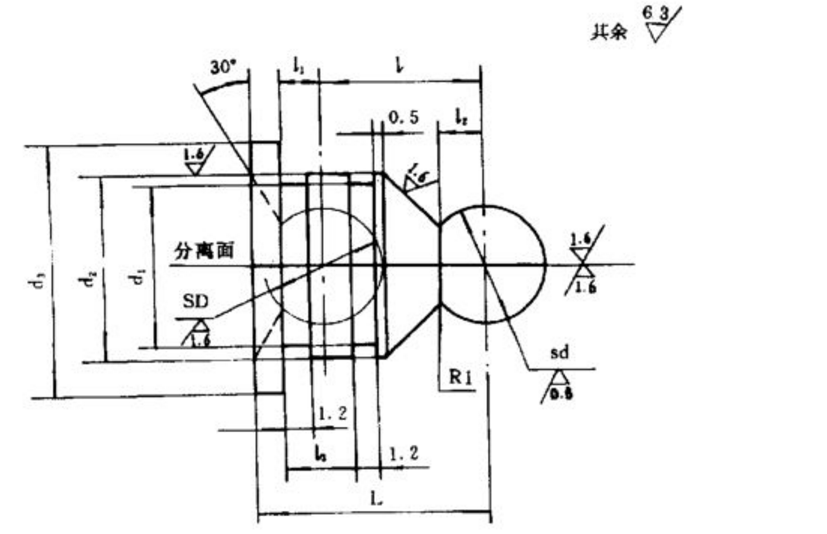

Half core head

Hemispherical rod

ROD

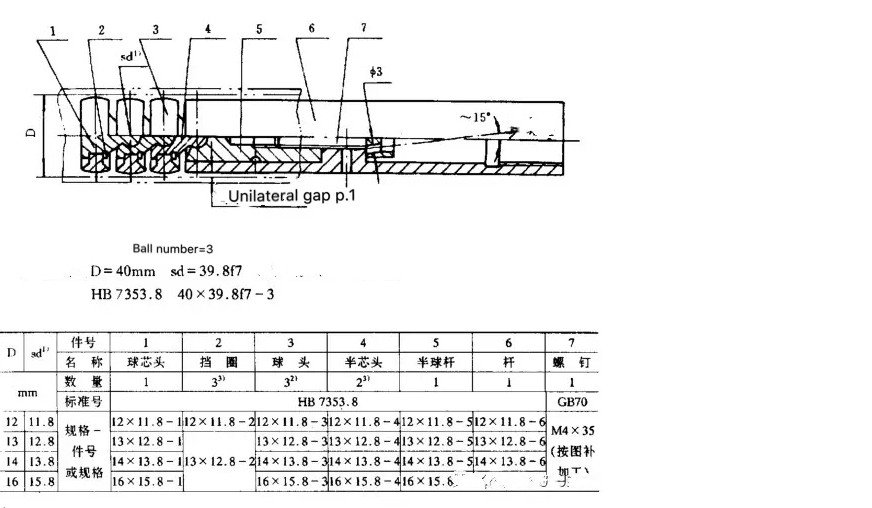

4.The following are the production standards of our Liye company.

Bent pipe technology is widely used in boiler and pressure vessel industry, central air conditioning manufacturing industry, automobile industry, aerospace industry, shipbuilding industry and other industries. The quality of the bent pipe will directly affect the reasonable structure of products in these industries Sex, safety, reliability, etc. Therefore, in order to bend high-quality pipe fittings, we should master the processing skills of pipe fittings under different technological conditions. For cold pipe bends, it is necessary to choose the formation of the core rod reasonably and master its correct usage.

According to different processing requirements, mandrels with different shapes should be selected. Under normal circumstances, the mandrel can be divided into two categories: one is a hard mandrel and one is a soft mandrel)

After the shape of the mandrel is selected, high-quality pipe fittings cannot be bent, and the gap between the mandrel and the inner diameter of the pipe is also an important factor affecting the quality of the bent pipe. If the diameter of the ball joint of the mandrel is too small, there may be wavy wrinkles on the inside of the arc when the tube is bent, and it may not play a role in preventing the outside of the arc from flattening; when the diameter is too large or the outer diameter of the ball joint is not smooth enough , It will hurt the tube wall, and the tube may bulge or even rupture outside the arc. Choosing a reasonable mandrel diameter and adequate lubrication is an indispensable element to ensure the quality of the elbow