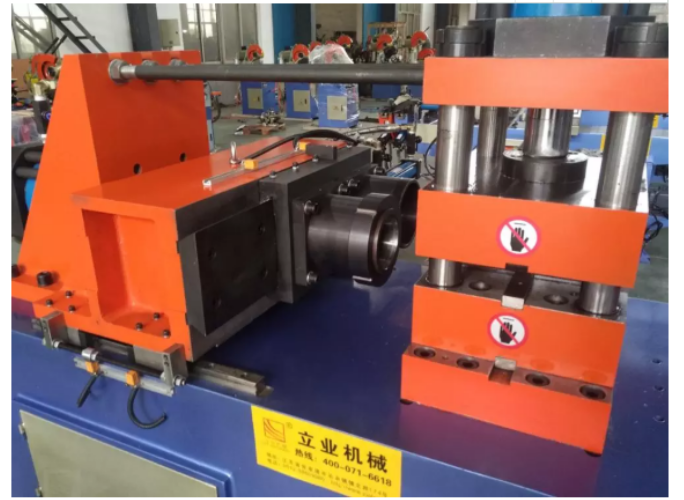

Operation of automatic cnc hydraulic end forming machine

Source:Liye Machinery(LYM) Co.,Ltd Release time:2021-10-08 13:36:23 Visit:733

Application of automatic cnc hydraulic end forming machine

1. Principle of operation: Through mechanical transmission, the steel pipe is driven to rotate and heated at one end of the steel pipe. When a certain temperature is reached, the heated steel pipe head is formed with a forming die until it reaches the required shape

2. How to use: Fix the tube on the tube shrinking machine and turn on the heater (ring). After the temperature is reached, the alloy mold is pushed, and the shape of the tube head meets the requirements.

3. Safety instructions:

-

When unloading the mold, the mold to be taken out must be moved to the bottom. When taking out the mold in the mold, one mold must be installed again, and four pieces cannot be taken out at the same time to avoid the inner mold from falling out.

-

For the semi-automatic tube shrinking machine, do not use excessive force when feeding, and should push forward evenly until it is in place to complete the removal of the tube material.

-

During the operation of the automatic shrinking machine, the operator should pay attention to adding lubricant to the guide rail not less than 4-5 times a day to ensure the normal operation of the guide rail.

-

The staff must wear earplugs or earmuffs during operation.

-

After get off work on the same day, you must organize the post and maintain the machine daily, and fill in the equipment maintenance form carefully. After get off work, the power switch and auxiliary gas must be turned off before leaving get off work.